Description

The battery winding process involves sequentially winding slit positive electrode sheets, separators, and negative electrode sheets around a fixed mandrel to form cylindrical, elliptical, or prismatic cells, which are then housed in metal casings.

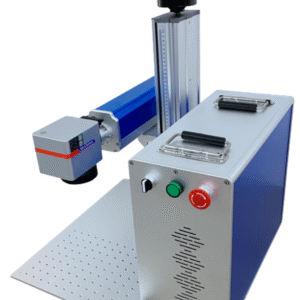

Product Overview

This machine is designed for prismatic lithium battery winding applications. It features:

- Separator roll feeding

- Manual sheet loading with automatic film pulling

- Insertable mandrel with trapezoidal interlocking design

- Adjustable cell width within a specified range

- Compact structure with user-friendly operation and maintenance

Key Features

- Single vertical plate structure with adjustable passive tension control for separator feeding

- Higher efficiency and better alignment compared to manual winding, suitable for diverse lab-scale cylindrical battery production

- Sheet feeding system with guide plates and vacuum-assisted positioning during winding

- Flexible cell dimensions:

- Length adjustment (30-100mm) via fixture modification

- Width adjustment (±10mm) via mandrel adaptation (larger changes require mandrel replacement)

- PLC control with touchscreen interface for parameter setting and step-by-step operation recall

- Interlocking trapezoidal mandrel with auto-retract function and configurable winding speed

- Optional automatic tape applicator for tab sealing

Technical Specifications

| Winding Method | Roll separator + sheet electrodes |

| Cell Dimensions | Width: 30-80mm; Length: 30-100mm; Max thickness: 10mm |

| Alignment Precision | ≤0.5mm deviation |

| Guide Channel Length | 1200mm (accommodates longer sheets) |

| Film Cutting | Automatic |

| Mandrel Type | Interlocking trapezoidal (standard 60mm width) |

| Winding Speed | Max 300 RPM (adjustable via touchscreen) |

| Separator Roll Size | Max Ø250mm |

| Power Supply | 220V±10%, 1kW |

| Air Pressure | 0.5-0.8MPa compressed air |

Precision winding (≤0.5mm misalignment) ensures consistent cell geometry

Adaptable tooling supports R&D prototyping and small-batch production

Vacuum-assisted handling minimizes electrode damage

Reviews

There are no reviews yet.