Description

Product Description

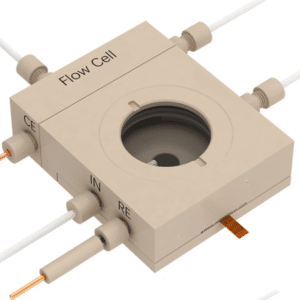

- The electrolytic cell adopts a sandwich structure and is divided into four parts: A, B, C, and D.

- Parts A and C have serpentine channels and are made of high-purity titanium.

- Part C can also be replaced with high-purity nickel.

- The B cavity is I-shaped as a whole, and the thickness of the middle part is 1.2mm. Using the B cavity, the distance between the cathode and anode (A and C) can be controlled within 1.6 mm.

- Part D is the plumbing fitting for the reference electrode.

- 3-in-1 Multifunctional

- Includes PEEK parts manufactured using Ensinger™ TECAPEEK (medical-grade)

Function 1

CO2 reduction gas diffusion electrolytic cell (as shown in the figure-Function 1).

● Plate A is used as a chamber for humid CO2 gas to pass through, a gas diffusion electrode (carbon paper) is placed between A and B, and plate B is used as a cathode liquid flow chamber.

● Anion exchange membrane and anode are placed between B and C. The anode can be a metal mesh loaded with a water-splitting catalyst, or a metal foam with water-splitting activity.

● Part C circulates neutral or alkaline electrolyte for water oxidation reaction.

● Part D places the reference electrode and also serves as the cathodic chamber liquid in and out. The reference electrode is inserted upside down at 45 degrees, which can quickly eliminate the interference of air bubbles.

Function 2

Solid-state electrolytic cell for producing pure liquid products (as shown in the figure-Function 2).

● Combine the three parts of ABC and remove part D, use the solid electrolyte based on ion exchange resin to replace the liquid electrolyte, avoid the introduction of ions, and directly realize the preparation of high-purity liquid products (in theory). The specific structure is as follows:

● Parts A and C have serpentine channels to prolong the residence time of the gas and improve the gas conversion rate.

● Plate A is used as a chamber for humid CO2 gas to enter, and a gas diffusion electrode (carbon paper) and anion exchange membrane are placed between A and B (to ensure sufficient contact, cold pressing or hot pressing process can be used).

● A cation exchange membrane and anode are placed between B and C. The anode can be a metal mesh loaded with a water-splitting catalyst, or a metal foam with water-splitting activity. Part C is passed through the acidic electrolyte to carry out the water oxidation reaction.

● Part B is the core component of the solid-state electrolytic cell. The cavity is I-shaped as a whole, and the thickness of the middle part is 1.2 mm. The middle part has a 1×1cm square through hole. The through holes can be filled with granular ion exchange resin as a solid electrolyte to replace the liquid electrolyte to realize the direct preparation of pure liquid fuel. By passing pure water into part B, the liquid product can be taken out of the reactor to obtain a pure liquid phase product aqueous solution free of anions and cations.

Function 3

CO2 reduction membrane electrode electrolytic cell

Combine parts A and C, remove parts B and D, and construct a membrane electrode electrolytic cell. The specific structure is as follows:

● Parts A and C have serpentine channels to prolong the residence time of the gas and improve the gas conversion rate.

● Plate A acts as a chamber for humidified CO2 gas, between A and C in sequence (from A to C order) place the gas diffusion electrode (carbon paper), anion exchange membrane or proton exchange membrane (to ensure full contact between gas diffusion electrode and ion exchange membrane, can use cold pressing or hot pressing process) and load Metal mesh with water-splitting catalyst (also metal foam with water-splitting activity).

● Part C is passed through neutral or alkaline electrolyte for water oxidation reaction.

Please feel free to contact us for more information.

Reviews

There are no reviews yet.