Global Trends in Solid-State Battery Development

The Evolution of Solid-State Batteries

The development of solid-state batteries dates back to the 1970s. In 1972, the concept of using lithium ions as an electrolyte in solid batteries was first introduced, marking the beginning of solid-state battery research. In 1983, Toshiba released the first practical Li/TiS2 thin-film solid-state lithium battery, laying the foundation for future advancements.

By the 2000s, France achieved the first commercial application, launching polymer-based solid-state batteries, initiating a phase of technological accumulation and breakthrough. The US, Germany, and Japan then accelerated the development of oxide and sulfide electrolytes, significantly enhancing battery performance. Since 2017, breakthroughs in new materials and manufacturing processes have propelled semi-solid batteries into rapid development. Companies like Toyota, QuantumScape, and Solid Power have announced large-scale production plans, aiming for full commercialization of solid-state batteries by around 2025.

Core Technological Developments

Solid-state batteries fall into three main categories:

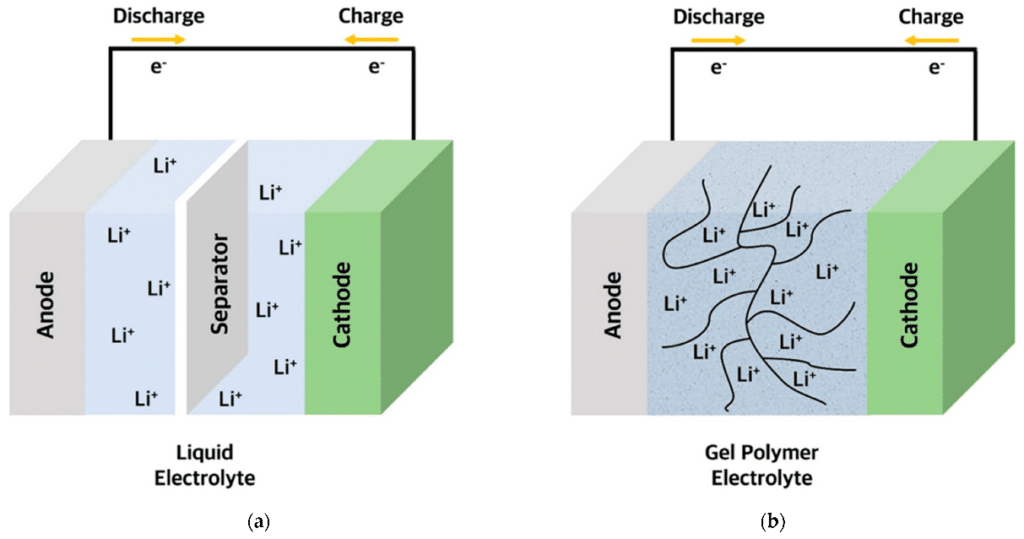

- Polymer Electrolytes

Simple to manufacture but with low ionic conductivity at room temperature, typically requiring heating above 60°C for normal operation.

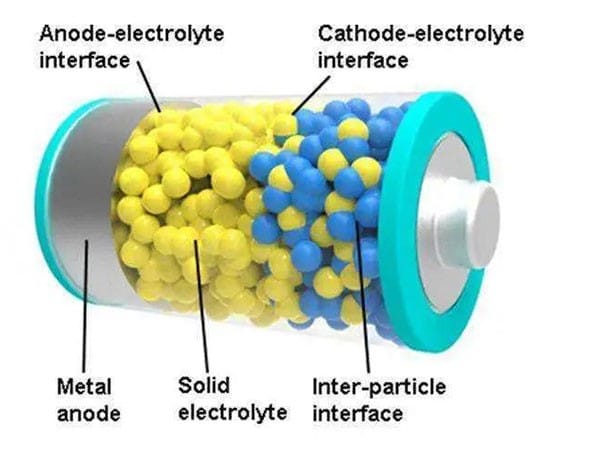

- Oxide Electrolytes (LLZO, LLTO)

High mechanical and chemical stability, suitable for high-energy density batteries, though interface resistance is high, necessitating further optimization. For instance, research from the Journal of Power Sources (2023) shows that using nanoscale oxide electrolytes can reduce interface resistance by approximately 30%, significantly enhancing battery cycle life.

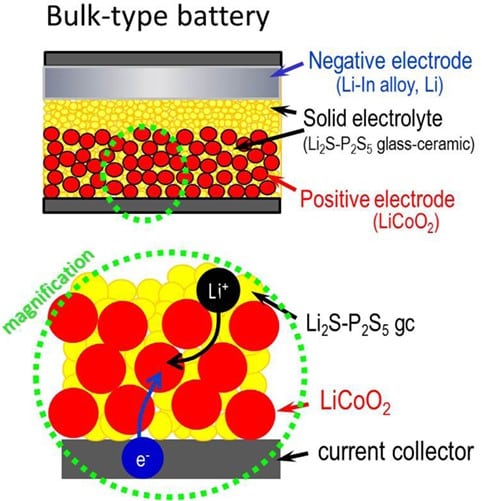

- Sulfide Electrolytes

Currently the most promising path, with high conductivity and good flexibility, making them easy to integrate with electrodes. However, sulfide materials decompose easily in air, requiring solutions for production environments and material stability. According to a journal Nanomaterials on November 5, 2024 study, sulfide electrolytes can achieve ionic conductivity of 10^-3 S/cm under specific synthesis conditions, approaching levels seen in liquid batteries.

Technical Development Analysis

The technological trajectory of solid-state batteries is diversifying, with different systems demonstrating unique advantages across various application scenarios. Polymer electrolytes are gradually maturing in wearable devices and consumer electronics, while oxide and sulfide batteries are favored for high-energy density applications such as electric vehicles and energy storage systems.

From an R&D and technological standpoint, sulfide batteries are emerging as a focus for major manufacturers due to their superior conductivity and compatibility. However, scaling production while lowering material costs and enhancing safety remains a key challenge.

Key Technical Challenges

- Interface Stability – High resistance at the electrode-electrolyte interface affects overall performance. Reducing this resistance is a core R&D priority. Recent experiments show that optimizing cathode coatings can lower interface resistance by approximately 20%.

- Electrolyte Conductivity – While sulfide and oxide electrolytes exhibit high ionic conductivity, they must reach levels comparable to liquid batteries at room temperature.

- Volume Expansion and Structural Design – The expansion of cathode and anode materials during charge and discharge cycles remains unresolved, affecting battery lifespan.

Market and Applications

Toyota, QuantumScape, and Solid Power have made significant advancements in sulfide and lithium-metal batteries. Toyota, in particular, plans to mass-produce sulfide-based solid-state batteries by 2025.

Singapore and Southeast Asia are actively engaging in solid-state battery research, collaborating with Japanese and European companies to accelerate the localization of solid-state battery materials and production lines.

Image Credits:

Solid-State Battery Structure: Future battery lab ([link]( https://shorturl.at/CVGi8)

Oxide Electrolytes (LLZO, LLTO): sciencedirect ([link]( https://shorturl.at/k0grX)

Polymer Electrolyte Battery: mdpi ([link]( https://shorturl.at/51EKj )

Sulfide Electrolytes: frontiersin (([link] https://shorturl.at/B8QCr)

Other Blog Posts You Might Like

Case Study: Relocation Solution for Electrochemical Equipment

Project Overview A research institution faced the daunting task of relocating two vital laboratory furnaces.…

Read moreReplacing Fossil Fuels: How Renewable Energy is Shaping the Future Energy Landscape

The global energy industry is undergoing a profound transformation, driven by the decreasing reliance on…

Read moreCompany insight: Strengthening capability Through Strategic Partnerships

At ANR, our commitment to innovation and excellence is driven by the quality of our…

Read more