Case Study: Relocation Solution for Electrochemical Equipment

Project Overview

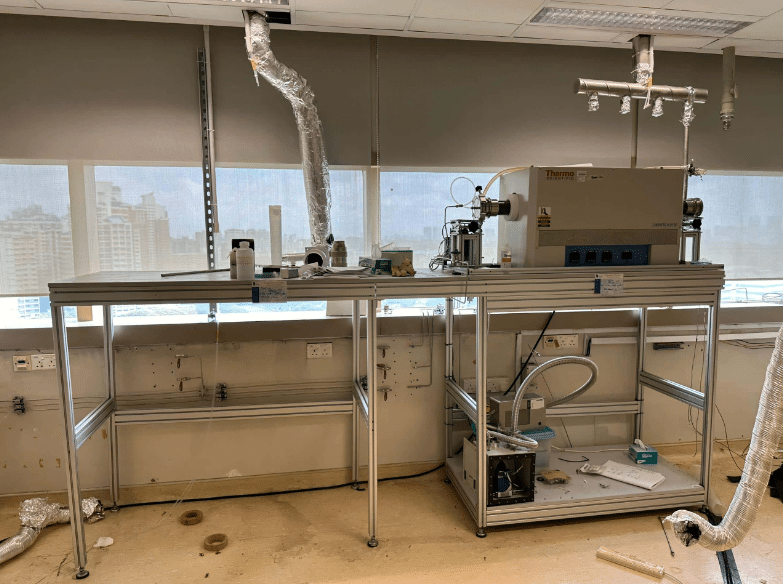

A research institution faced the daunting task of relocating two vital laboratory furnaces. Due to the equipment’s advanced age, we encountered several challenges during the relocation. This task not only involved the complex process of disassembly, transportation, and reinstallation in a new lab, but also the protection of the equipment and training on its use.

Challenge

Relocating laboratory equipment is a complex and demanding task, especially when the equipment is outdated and unfamiliar to current staff:

- Outdated Equipment: Although the furnaces had low usage, they were obsolete, with the manufacturer no longer providing maintenance or manuals. The original lab personnel had departed, leaving the current staff in a difficult position, struggling to operate equipment they were unfamiliar with.

- Professional Disassembly: Without manuals, we had to analyze the usage and installation methods of the equipment from scratch, documenting every detail to ensure nothing was missed during disassembly.

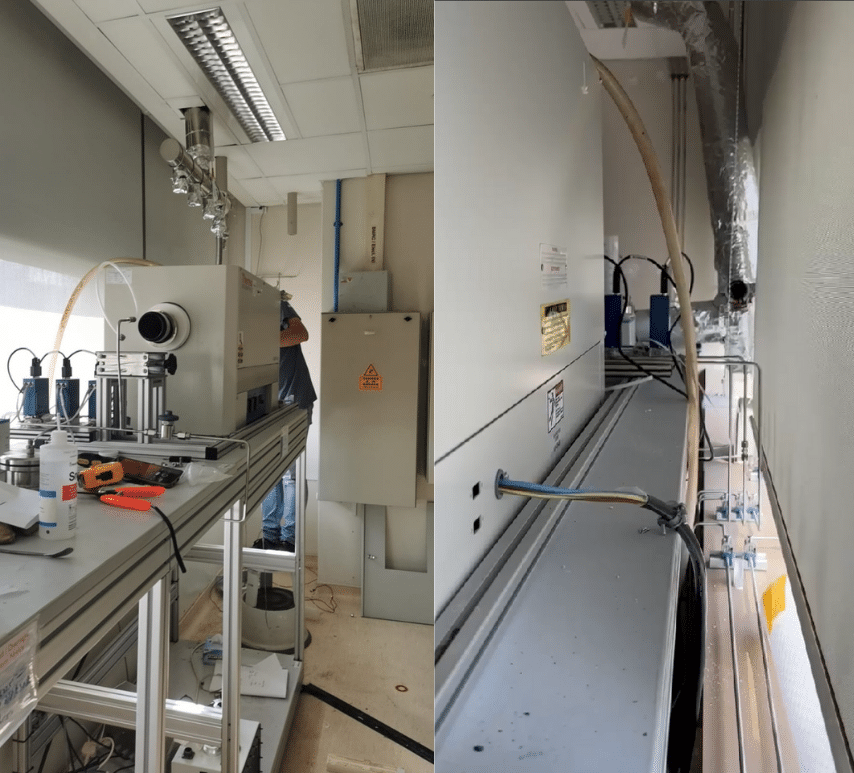

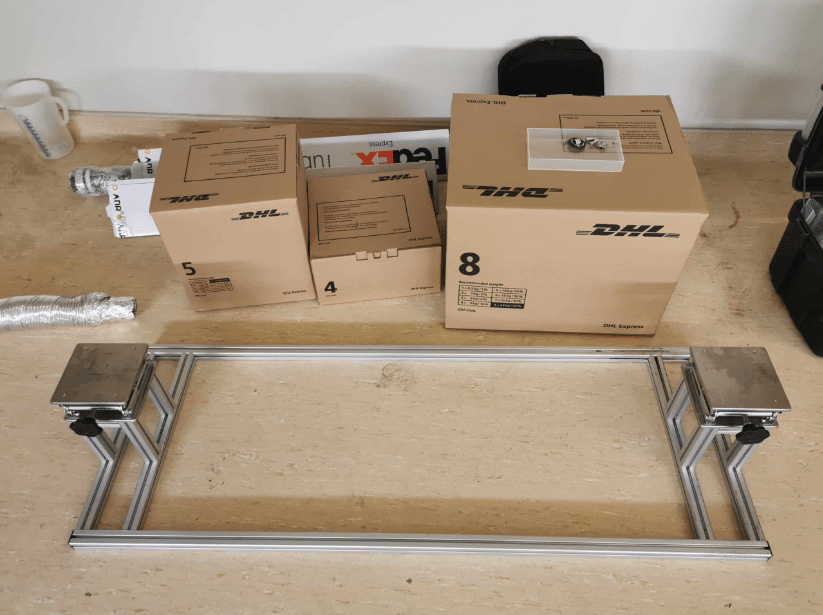

- Safe Transport: Each component had to be photographed during disassembly to ensure they could be reassembled without damage after transportation.

- Reinstallation and Training: After reassembling the equipment at the new location, we needed to train the current lab personnel on its proper operation.

Solution

ANR provided professional and effective service, resolving all encountered challenges., effectively addressing all challenges:

- Experienced Professional Team: Our technicians meticulously disassembled each component and gas pipe, safely transported the furnace, and reconnected all the equipment at the new location. They conducted thorough calibration and validation. Every step was documented with photographs to ensure that the reinstallation after the relocation would be error-free.

- Customized Relocation Plan: Due to the inherent risks associated with the furnaces, we needed to visit the new site to assess the situation and evaluate the best location for placing the equipment before it was transported. This was to ensure that the gas emissions from the furnace would remain within safe limits. Therefore, a detailed relocation schedule and site survey plan were essential to ensure that every step was thoroughly prepared. This included listing the necessary tools and materials and assessing the site conditions to ensure safe placement and usage.

- Safety and Compliance: We adhered to all safety regulations, provided comprehensive insurance coverage, and ensured all relocation forms were accurately submitted.

- Project Management and Communication: We maintained close communication with the client, providing regular updates to ensure smooth coordination and transparency.

Results

- The furnaces were successfully disassembled, transported, and reinstalled without any damage.

- Upon receiving the client’s enquiry, we conducted site surveys at both the original and new locations. From assessment to finding a mover and providing a solution, the entire process took about 3 days.

- Throughout the entire relocation process, we provided on-site support from start to finish.

- We ensured that the lab personnel received training on the use and maintenance of the furnace, and we continued to provide technical support thereafter.

Conclusion

Relocating laboratory equipment involves much more than simply moving it from one place to another. We understand the unique needs of such a transition and are committed to providing seamless and efficient lab relocation services. At ANR, our mission is simple yet profound: Freeing you to focus on science. While our four core services—procure, testing, publish, and customise —form the foundation of our offerings, we also extend our expertise to help clients with laboratory-related services.

Other Blog Posts You Might Like

Understanding Electrolytic Cells: Types, Components, and Applications

An electrolytic cell is an essential electrochemical device that drives a non-spontaneous redox reaction using…

Read moreThe Core Logic Behind Electrolyte Formulation Development

An Engineering Perspective on Performance Trade-offs Electrolyte formulation is often described as a process of…

Read moreGlobal Trends in Solid-State Battery Development

The Evolution of Solid-State Batteries The development of solid-state batteries dates back to the 1970s.…

Read more