Build, Print, Cure: Materials That Make 3D Printing Work

As 3D bioprinting continues to advance rapidly, the performance and functionality of materials have become key drivers in turning laboratory research into real-world applications. Among these, photocurable biomaterials stand out for their precise printability and excellent biocompatibility, making them essential in tissue engineering, drug delivery, and disease modeling. Our company specializes in supplying high-performance photocurable biomaterials and has developed a comprehensive portfolio that includes natural polymers, synthetic polymers, and functionalized biopolymers. Our lineup of 11 materials—such as Gelatin Methacrylate (GelMA), Hyaluronic Acid Methacrylate (HAMA), photocurable silk fibroin, and fluorescent-labeled GelMA—empowers researchers to build complex, biofunctional 3D structures more efficiently and reliably.

| Material | Key Features | Main Applications | |

| 1. | GelMA (Gelatin Methacrylate) | Rapid photocuring; tunable stiffness mimicking soft to stiff tissues | 3D cell culture, tissue regeneration |

| 2. | Porous GelMA | Enhanced nutrient/oxygen diffusion; supports high cell density | Vascularized tissue models, high-density 3D cultures |

| 3. | Fluorescent GelMA | Stable red/green/blue fluorescence; covalent labeling | Cell tracking, biosensing, diagnostic models |

| 4. | HAMA (Hyaluronic Acid Methacrylate) | High moisture retention; excellent biocompatibility | Soft tissue models (e.g., cartilage, neural tissue) |

| 5. | Photocurable Silk Fibroin (SilMA) | High mechanical strength; biodegradable; printable | Structural tissue engineering, drug delivery |

| 6. | AlgMA (Methacrylated Alginate) | Tunable viscosity; biocompatible; blends well with GelMA/HAMA | Skin, cartilage, soft tissue scaffolds |

| 7. | F127DA (Polyether F127 Diacrylate) | Self-assembling micelles; high toughness | Load-bearing soft tissues, injectable bioinks |

| 8. | PCLMA (Polycaprolactone Methacrylate) | Low viscosity; fast curing at 40–50°C | Microfluidics, implantable scaffolds |

| 9. | Acrylated RGD Peptide (EFL-Pep-RGDfKAC) | Covalent cell-adhesive peptide; no leaching | Enhanced cell adhesion, organ-on-chip, bioinks |

| 10. | DexMA (Methacrylated Dextran) | High solubility; safe; tunable elasticity | Controlled release, soft hydrogel bioprinting |

| 11 | ChSMA (Methacrylated Chondroitin Sulfate) | Mimics cartilage–bone interfaces; high biocompatibility | Osteochondral repair, craniofacial tissue engineering |

1. Gelatin Methacrylate (GM Series)

Gelatin Methacrylate (GelMA) is a photocurable hydrogel that rapidly crosslinks into a gel within 10 seconds under visible light exposure at 405 nm. This material is widely used in 3D cell culture, bioprinting, and regenerative medicine research. Our GM series offers GelMA with tunable mechanical properties, enabling researchers to simulate a broad range of tissue stiffness—from ultrasoft liver tissue to stiffer cartilage-like environments. In addition to the materials, we also provide a complete suite of supporting tools and equipment to facilitate your experimental workflow.

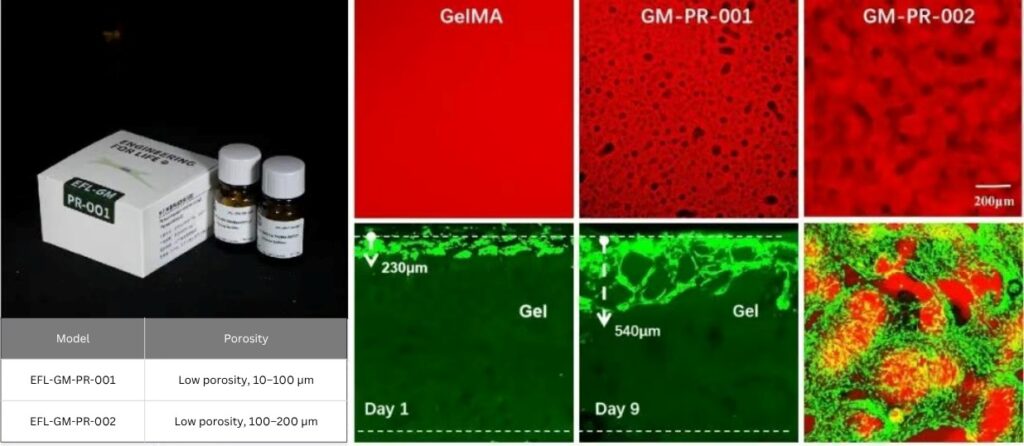

2.Porous GelMA (GM-PR Series)

The GM-PR series features porous GelMA hydrogels engineered to enhance mass transport and cellular interactions within 3D culture systems. Compared to conventional non-porous GelMA, these porous variants significantly improve the diffusion of nutrients, oxygen, and signaling molecules, while also providing additional space for cell growth and proliferation.

This structural advantage makes porous GelMA particularly valuable for applications requiring high cell density, vascularization, or tissue remodeling. Whether used independently or in hybrid hydrogel systems, EFL-GM-PR hydrogels demonstrate superior performance in sustaining long-term and functional 3D cell cultures.

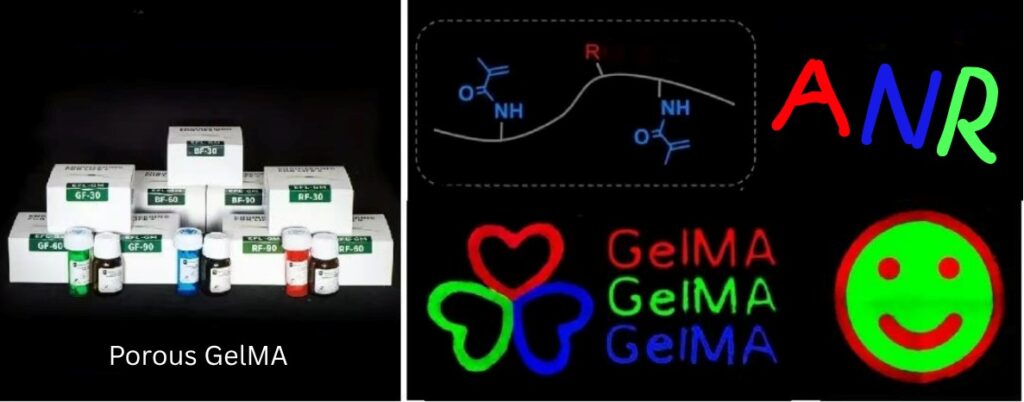

3.Fluorescent GelMA (GM-RF/GF/BF Series)

The GM-RF/GF/BF series comprises fluorescent GelMA hydrogels, created by covalently grafting fluorescent molecules onto the GelMA backbone. Depending on the type of fluorophore used, the hydrogels emit distinct fluorescence colors—such as red, green, or blue—while preserving GelMA’s excellent biological and mechanical properties.

Unlike traditional methods that rely on physical blending or electrostatic adsorption (which often result in fluorophore diffusion or uneven imaging), this covalent modification ensures stable, uniform fluorescence distribution throughout the hydrogel network.

Fluorescent GelMA hydrogels offer powerful functionality in fields like 3D bioprinting, biosensing, disease diagnostics, cell tracing, and biomimetic actuation, making them highly versatile for research and innovation.

4.Methacrylated Hyaluronic Acid (HAMA Series)

Hyaluronic acid (HA), commonly referred to as hyaluronan, is a naturally occurring polysaccharide with outstanding moisture retention and biocompatibility. It is highly concentrated in tissues such as the brain, synovial fluid, and vitreous body, and plays a crucial role in various biological processes including cell proliferation, differentiation, morphogenesis, inflammation, and wound healing.

The HAMA series features methacrylated HA (HAMA), which introduces photocurable functionality while retaining the bioactivity of native HA. When combined with EFL’s GelMA hydrogels, HAMA enables the creation of biomimetic microenvironments that closely resemble soft tissues like cartilage and neural tissue, leading to enhanced 3D cell culture performance and optimized bioink formulations for advanced bioprinting applications.

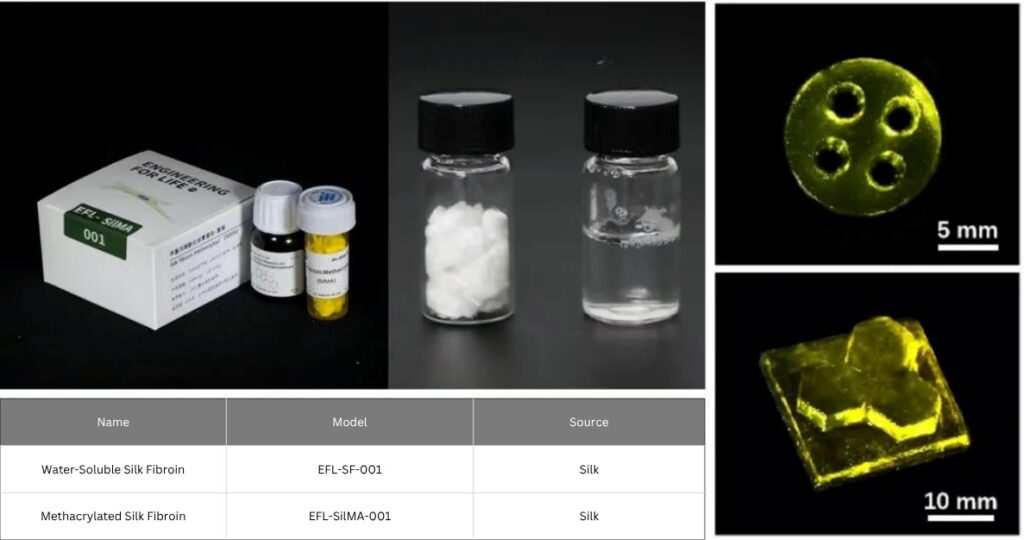

5.Photocurable Silk Fibroin (SF / SilMA Series)

Silk fibroin (SF), derived from degummed silkworm silk, is a FDA-approved natural biomaterial known for its excellent biocompatibility, mechanical strength, and biodegradability. To meet diverse application needs, ANR offers a series of silk fibroin-based hydrogels with unique properties and processing capabilities.

- The SF series offers water-soluble, stable silk fibroin suitable for blending with other hydrogels such as GelMA and HAMA. Its versatility allows researchers to tune biological and mechanical performance for a wide range of biomedical applications.

- The methacrylated version (SilMA) combines biocompatibility with photocurable functionality, enabling efficient and high-resolution printing via projection-based 3D bioprinting platforms.

These materials open new possibilities in tissue engineering, drug delivery, and biofabrication, especially where structural precision and biological functionality are required.

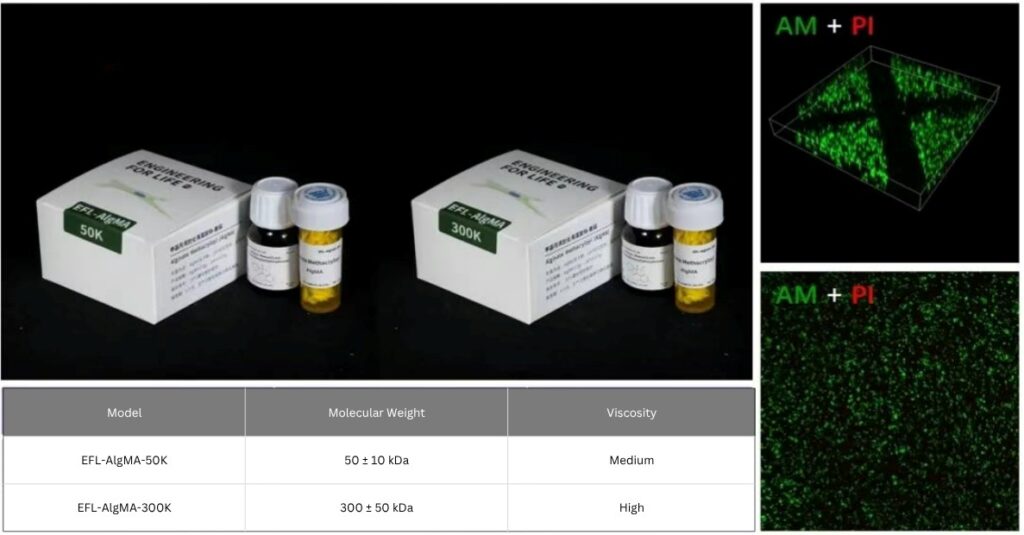

6.Photocurable Alginate (AlgMA Series)

Methacrylated alginate (AlgMA) is a versatile, photocurable derivative of sodium alginate that has been widely applied in numerous biomedical research areas—including tumor modeling, cell encapsulation, wound dressings, controlled drug release, and dental impression materials.

The AlgMA series offers high-quality AlgMA materials that can be used alone or in combination with GelMA and HAMA hydrogels to create composite systems. These blends allow researchers to better simulate in vivo tissue microenvironments such as skin, cartilage, and soft connective tissues, resulting in improved 3D cell culture fidelity and optimized bioink formulations for bioprinting and tissue engineering.

With tunable viscosity, gelation speed, and mechanical strength, AlgMA provides a reliable foundation for developing biologically relevant, high-resolution structures.

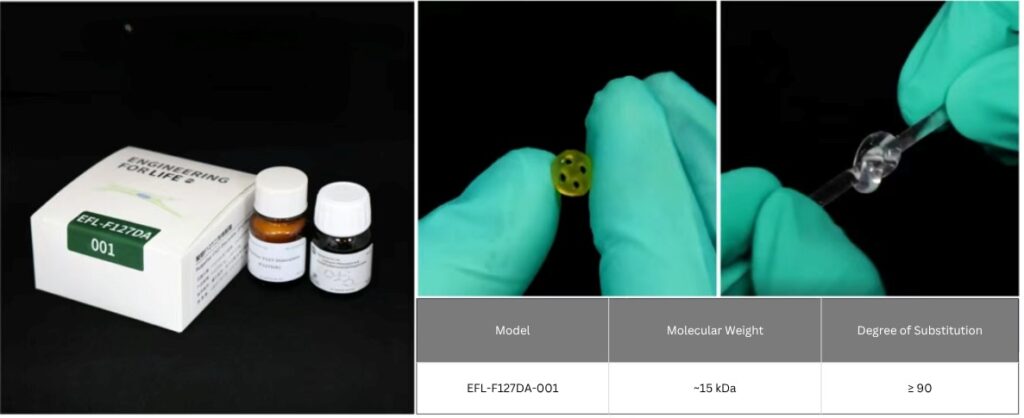

7.Photocurable Polyether F127 Diacrylate (F127 DA Series)

Polyether F127, also known as Poloxamer 407, is a synthetic A-B-A type triblock copolymer composed of polyethylene glycol (PEG) and polypropylene glycol (PPG). By introducing diacrylate groups to its terminal chains, we obtain Polyether F127 Diacrylate (F127DA), a photocurable variant capable of rapid crosslinking under light exposure.

F127DA exhibits unique self-assembling behavior in aqueous environments, where it forms nanoscale micelles. Upon photocuring, these micelles contribute to the formation of hydrogels with exceptional mechanical performance, characterized by high strength and remarkable toughness.

The F127DA series is particularly suited for applications requiring robust yet flexible hydrogel matrices, such as load-bearing soft tissue engineering, injectable scaffolds, and bioinks with enhanced durability.

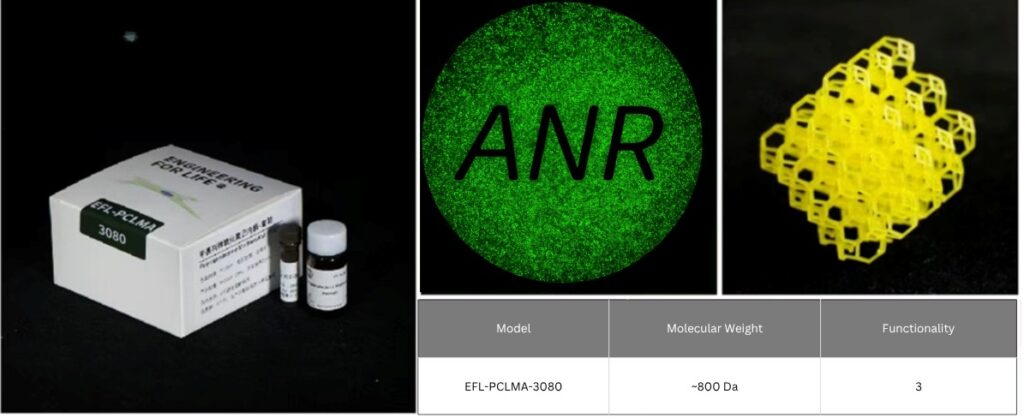

8.Photocurable Poly(ε-caprolactone) Methacrylate (PCLMA Series)

Poly(ε-caprolactone) (PCL) is a synthetic, hydrophobic aliphatic polyester that has been FDA-approved for clinical use due to its excellent biocompatibility and biodegradability. The EFL-PCLMA series introduces a photocurable version of PCL—EFL-PCLMA-3080—functionalized with methacrylate groups to enable rapid crosslinking.

EFL-PCLMA-3080 exhibits good flowability at 40–50°C and solidifies in under 10 seconds under light exposure. Its low viscosity, fast curing, and high resolution make it particularly well-suited for projection-based photopolymerization (DLP/SLA 3D printing) to fabricate complex, high-precision structures.

Ideal for load-bearing tissue scaffolds, microfluidic devices, and implantable biomaterials, PCLMA bridges the gap between mechanical strength and biological performance in next-generation biomanufacturing.

9.Acrylated RGD Peptide (EFL-Pep-RGDfKAC)

To enhance the cell-adhesive properties of photocurable hydrogels, EFL-Pep-RGDfKAC offers a functionalized RGD peptide modified with an acrylate group, allowing for direct photopolymerization into hydrogel networks.

The acrylated RGD peptide contains a polymerizable vinyl group, enabling it to form stable covalent bonds with a variety of EFL’s photocurable hydrogels, including PEGDA, AlgMA, HAMA, F127DA, and DexMA. This covalent incorporation ensures uniform peptide distribution and prevents leaching, providing a robust platform for integrin-mediated cell attachment.

Incorporating EFL-Pep-RGDfKAC into your hydrogel system can significantly boost cell adhesion, spreading, and migration, making it an essential additive for applications such as tissue engineering, organ-on-chip models, and bioprinting bioinks.

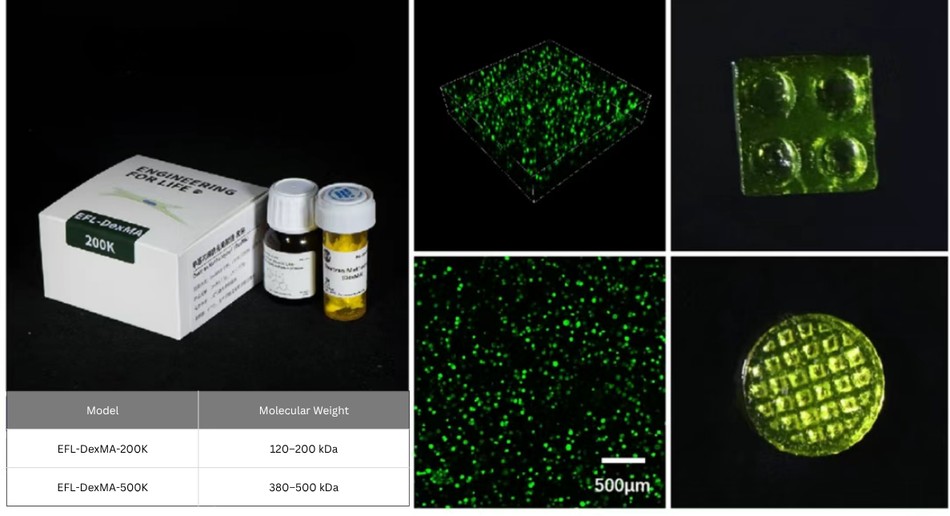

10.Methacrylated Dextran (DexMA Series)

Dextran is a highly water-soluble, biocompatible polysaccharide known for its low protein adsorption, chemical modifiability, and excellent safety profile, making it a valuable material in biomedical applications such as thrombosis prevention, blood viscosity reduction, and drug delivery.

The DexMA series features methacrylated dextran (DexMA), which combines dextran’s native biofunctionality with photocurable capability. DexMA hydrogels form within 10 seconds under visible light, offering a fast, efficient, and cytocompatible approach for hydrogel fabrication.

With its stable physicochemical properties and high material expandability, DexMA can be tuned to achieve a wide range of viscoelastic profiles, making it ideal for bioink development, soft tissue engineering, and controlled release systems.

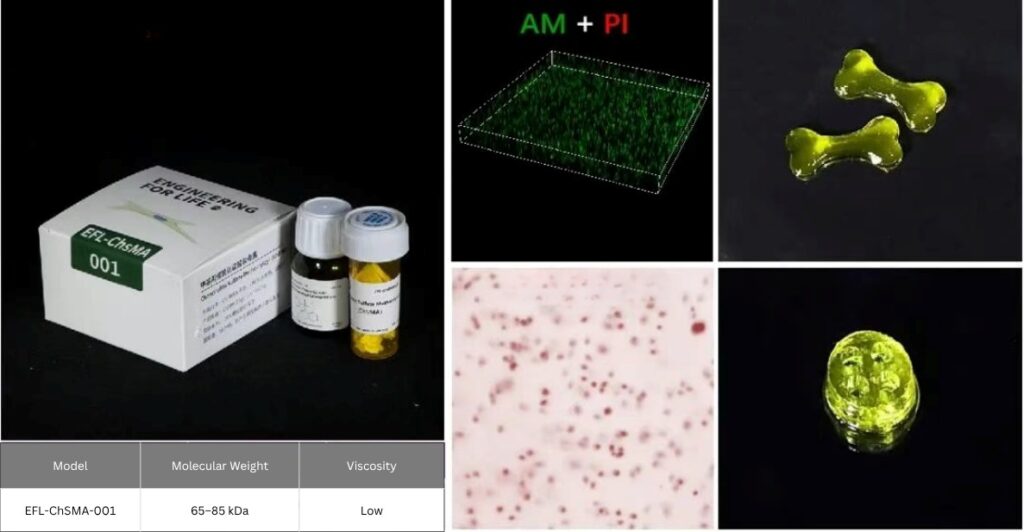

11.Photocurable Chondroitin Sulfate (ChSMA Series)

Methacrylated chondroitin sulfate (ChSMA), part of the ChSMA series, is a versatile, bioactive hydrogel material widely used in biomedical research fields such as osteoarthritis therapy, articular cartilage repair, and cranial bone reconstruction.

With excellent biocompatibility and tunable viscoelastic properties, ChSMA supports a wide range of application needs. When blended with GelMA or HAMA hydrogels, it helps recreate the complex microenvironments of bone–cartilage interfaces and skin tissues, enhancing both the structural fidelity and cellular performance of 3D constructs.

ChSMA’s light-curable nature and chemical compatibility make it a powerful additive for improving 3D cell culture systems and formulating high-performance bioinks for advanced tissue engineering applications.

With the continuous advancement of 3D bioprinting and tissue engineering, the need for versatile, biocompatible, and photocurable materials has never been greater. At ANR, we delivering a comprehensive portfolio of cutting-edge bioinks—from GelMA and HAMA to functionalized peptides and methacrylated glycosaminoglycans—to empower researchers and engineers in building the next generation of biomimetic tissues and organ models.

Other Blog Posts You Might Like

Replacing Fossil Fuels: How Renewable Energy is Shaping the Future Energy Landscape

The global energy industry is undergoing a profound transformation, driven by the decreasing reliance on…

Read moreElectrocatalysis: A Key Technology for Energy Storage and Conversion

As the world transitions towards renewable energy, electrocatalysis has become a crucial technology for energy…

Read moreEvent Recap: Future Development of Lithium-Ion Batteries – From ICAMEEH 2024

From September 24 to 27, 2024, we are honored to be the industrial exhibitor of…

Read more