Description

Welding is a critical manufacturing process that uses heat, pressure, or both to create atomic-level bonding between metal components (such as tabs and connectors) inside batteries, ensuring stable electrical connections that enhance performance and safety. Common methods include resistance welding, laser welding, and ultrasonic welding.

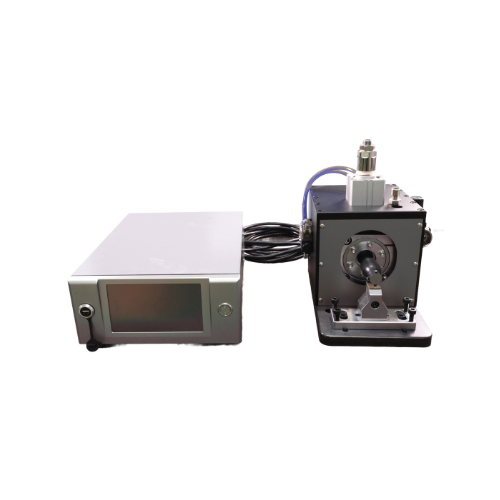

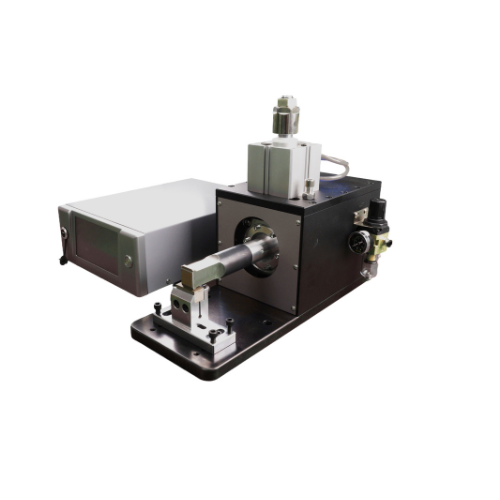

Product Overview

This compact, user-friendly welder is designed for both wound and stacked battery cell assembly. It converts high-power ultrasonic oscillations into mechanical energy at the welding interface, activating metal lattice particles to create molecular-level bonds without filler materials.

Key Advantages

- Superior conductivity: Near-zero resistance at weld points

- Self-cleaning capability: Eliminates need for surface pretreatment (tolerates oxides/contaminants)

- Filler-free process: No solder or flux required

- Durable tooling: Wear-resistant sonotrodes for extended service life

- Precision joints: 1.Maintains base metal microstructure (below annealing temp) 2. Stronger than conventional welds with clean, uniform interfaces

- Eco-friendly operation: 1. Spark-free with no fumes/air pollution 2. 0.01-25 second cycle times

| Operating Voltage | AC220V/50Hz |

| Air Pressure | 0.5-0.7MPa |

| Frequency | 40kHz |

| Power Input | 0-1000VA |

| Weld Time | 0-15 sec adjustable |

| Weight | ~60kg |

| Controller Dimensions | 360×480×200mm |

| Generator Dimensions | 300×460×270mm |

Industry Applications:

Tab-to-busbar welding in Li-ion/pouch cells

Multi-layer foil stacking for high-current electrodes

Research labs developing next-gen battery designs

The HS-DH1000 combines production-grade reliability with R&D flexibility – contact us to discuss your specific welding requirements.

Reviews

There are no reviews yet.