Description

Slurry coating refers to the process of uniformly applying a paste-like polymer, molten polymer, or polymer solution onto a substrate (typically metal foils such as copper or aluminum in lithium batteries) to form composite films or electrode sheets. For lithium-ion batteries, the coating process is one of the key steps in electrode manufacturing.

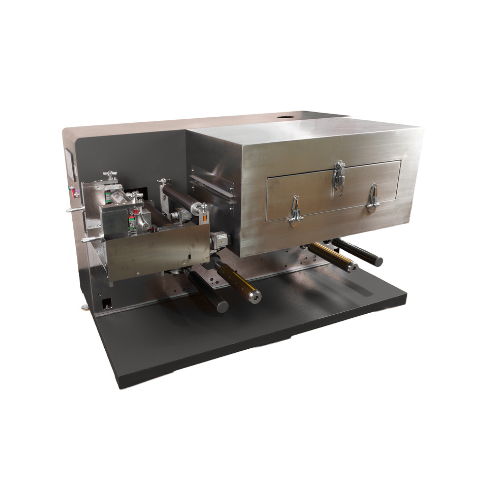

Product Overview

The experimental coating machine is a three-roll transfer coating device designed for surface coating processes on various substrates. It is particularly suited for the lithium-ion battery industry, offering precision and consistency comparable to production-grade equipment while maintaining ease of use for researchers. With excellent drying performance, it is an ideal choice for R&D and certification in lithium-ion batteries, supercapacitors, nickel-based batteries, and other secondary batteries.

Key Features

- Substrate tension control for stable web handling, equipped with a deviation correction system.

- Hot-air drying oven with dual-sided airflow for superior drying results.

- Three-roll transfer coating with a wide coating window.

- Adjustable blade metering paired with precision tuning mechanisms for high coating accuracy.

- PLC control and touchscreen operation for user-friendly experience.

- Optional solvent recovery system (customizable).

| Coating Method | Three-roll transfer continuous coating | Tension Control | Max 60N (adjustable) |

| Roller Width | 330mm | Display Precision | 1μm |

| Coating Width | Max 300mm | Drying Temperature | RT–120°C (adjustable) |

| Mechanical Speed | Max 900mm/min | Drying Unit | Standard hot-air drying |

| Coating Accuracy | ±3μm (edge deviation ±5μm) | Compressed Air | 0.5–0.7MPa |

| Coating Thickness | 40–200μm (depends on slurry) | Power Supply | 3-phase 380V/50Hz |

| Thickness Adjustment | Manual free-tuning | Max Power Consumption | 5kW |

| Roll Diameter | Φ250mm | Dimensions | 1800×1200×1200mm |

| Winding Accuracy | ±0.5mm | Weight | ~1 ton |

Key Terms:

Slurry : Paste-like mixture for electrode coating.

Three-roll transfer: Coating method using three rollers for precise material application.

Hot-air drying oven : Drying system with controlled airflow.

Deviation correction: Mechanism to align substrate during coating.

PLC control : Automated control via programmable logic controller.

Reviews

There are no reviews yet.