Description

Product Overview

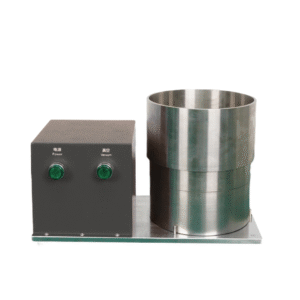

This product is an efficient, integrated system for real-time dispersion and mixing. It is ideal for slurry preparation processes in battery R&D and production, including cathode/anode material mixing and powder-liquid homogenization. By mixing under vacuum, it effectively eliminates bubbles and enhances material filling consistency and reproducibility.

Key Features

Reverse Rotation Mixing: Designed with reverse rotation for high-viscosity slurry, delivering high-speed, uniform mixing.

Built-in Vacuum System: Effectively removes air bubbles during the mixing process to ensure material consistency.

Multi-Speed Control: Supports three-speed settings for precise control over rotation speed and duration.

Modular Mixing Shaft: Allows flexible configuration of shaft structures and sizes to suit different materials and batch volumes.

Stable Support Frame: Square base ensures safety and stability during vacuum mixing operations.

Compact & Aesthetic Design: Vertical layout saves space and features a clean, professional appearance.

Small Footprint: Lightweight and space-efficient, ideal for lab-scale applications.

Technical Specifications

| Parameter | Specification |

| Mixing Speed | Up to 600 RPM |

| Speed Settings | Three-stage adjustable speed |

| Mixing Container | 500 mL Stainless Steel Vacuum Jar (customizable) |

| Mixing Time | Adjustable from 0–600 minutes |

| Power Supply | AC220V |

| Rated Power | 200W |

| Dimensions | Approx. 330 mm × 320 mm × 570 mm (L × W × H) |

| Weight | Approx. 35 kg |

| Vacuum Pressure | ≤ -0.08 MPa (Built-in vacuum pump) |

Note: Custom container sizes are available upon request.

Reviews

There are no reviews yet.